Media Center

A multimedia mosaic of moments at GIST

GIST Excellence

Development of new manufacturing technology for high-efficiency organic solar cell modules

- 김슬혜

- REG_DATE : 2014.03.28

- HIT : 840

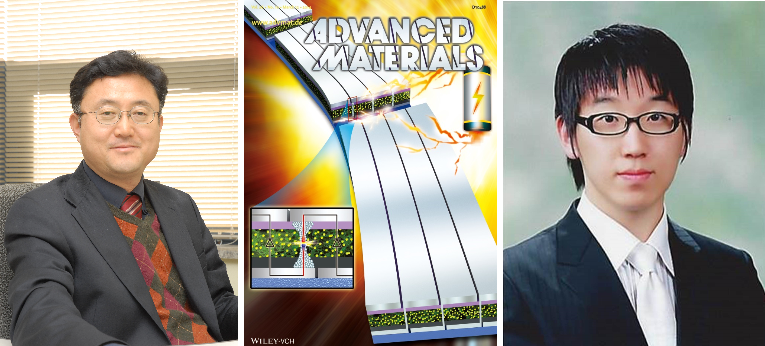

Development of new manufacturing technology for high-efficiency organic solar cell modules - published as cover article of Advanced Materials dated March 15 - expected to advance the commercialization of solar cells by maximizing effective areas of module □ A group of Korean researchers developed a technology to substantially increase the module efficiency of an organic solar cell* which is touted as a new source of energy, and to simplify its manufacturing process. This technology maximizes the surface to absorb sun light and produce electric power and is expected to suggest a clue to research on the commercialization of printing-type organic solar cells. (* organic solar cell: a solar cell which uses organic materials such as plastic as the main material of photoactive layers.) o This research was led by Prof. Lee Kwang-hee (corresponding author) of the School of Materials Science and Engineering at Gwangju Institute of Science and Technology (GIST, President ž Young Joon Kim) and conducted by researcher Kang Hong-gye (lead author) in the doctoral program with the sponsorship from the Senior Researchers Support Project (take-off research) jointly implemented by the Ministry of Science, ICT and Future Planning and National Research Foundation of Korea and National Core Research Center (NCRC). The research finding was published as the Cover Article of Advanced Materials, an international journal of material science, dated March 15, 2014. □ Unlike inorganic solar cells which use silicon or compound semiconductor as main material, organic solar cells can be manufactured by a solution process and are flexible. Its potential application to solar power generation on various types of curved surface draws much attention. o The commercialization of organic solar cells requires a continuous printing process for production, to which a technology connecting small solar cells in series on a large board surface is essential. □ The research team successfully connected organic solar cells in series by applying electric field to the joints between organic solar cells which were manufactured with silver nano-particles added, thus created metal filament nano-electrodes between the cells. o The new method of connecting small-surfaced organic solar cells in series by electrodes, without patterning, is expected to contribute to the commercialization of large-surfaced printing-type organic solar cells. □ In particular, the reduced loss of surface caused by series connection increases effective area*, thereby raising large-surfaced module efficiency to on par with the small-surfaced unit device efficiency. o The efficiency of modules manufactured by the technology was found to have increased from the current to 60~70% to 90% of small-surfaced unit device. □ With previously technologies, small-surfaced organic solar cells were patterned at micrometers apart and then were connected in series, which was quite a complicated process, and some of the surface areas had to be used for series connection. As a result, there was a limit in expanding effective areas. o Prof. Lee Kwang-hee said “Our research finding suggests a new manufacturing method of organic solar cells which maximizes effective areas, and will help to advance the commercialization of printing-type organic solar cells.”

(title: A New Architecture for Printable Photovoltaics Overcoming Conventional Module Limits)