Media Center

A multimedia mosaic of moments at GIST

GIST Excellence

“Geckoprinting” Technique Developed for Wearable Devices

- 정명식

- REG_DATE : 2014.07.24

- HIT : 697

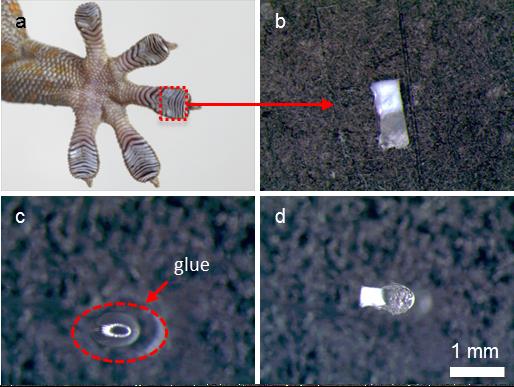

A Korean research team has developed a new technique to easily attach microelectronic devices onto clothes or skins by transfer printing with setal arrays found on the sole of geckos, which have a remarkable ability to switch adhesion mechanically on and off. Named “geckoprinting,” this new method is expected to help overcome the limitations of conventional transfer printing techniques that require high temperature, high pressure, or glue, and contribute to the commercialization of flexible electronic devices and high-performance wearable devices. Prof. Jongho Lee Mr. Jaeyoung Jeong The research was led by communicating author Prof. Jongho Lee of GIST School of Mechatronics and conducted by first author Mr. Jaeyoung Jeong of LS Mtron Ltd., a GIST alumnus with a master’s degree, and was funded by the Young Researcher Program and the Space Core Technology Development Program of the National Research Foundation of Korea and the Ministry of Science, ICT, and Future Planning. The research results were published as an online paper dated July 23, 2014 on the Journal of the Royal Society Interface (Title: Geckoprinting: assembly of microelectronic devices on unconventional surfaces by transfer printing with isolated gecko setal arrays). To manufacture high-performance wearable devices, microelectronic devices are first fabricated on semiconductor substrates, and then are picked and transfer-printed onto films, clothes, or other surfaces. In this transfer printing process, a stamp is needed to pick and place the microelectronic devices. The stamp used in transfer printing must have a strong adhesion when picking the devices from the substrate and a weak adhesion when placing them onto new surfaces. However, conventional techniques require high temperature, high pressure, or glue for successful results, which limits their applicability in broader circumstances. The research team employed the setal arrays from the sole of geckos in the stamp for transfer printing, taking note of the lizards’ remarkable ability to move freely on walls and ceilings. They made their “geckostamp” by taking seta from toes of living geckos (the setal arrays naturally regenerate and can be retaken in about two months) and fixing them onto glass under the microscope. Preparation of the setal stamp a) Setal array on the toes of gecko. b) Setal array separated from gecko. Cut seta to make setal stamp for transfer printing. c) The glue dropped on a glass plate to fix the separated setal after cleaning the glass plate with acetone. d) Prepared setal array after drying for 90 min. Using the geckostamp, the research team succeeded in transfer printing microscale silicon films and gallium arsenide (GaAs) solar cells onto insect wings and tree leaves, respectively. They confirmed that the electric characteristics of the silicon films and solar cells remain the same before and after the transfer printing. This new technique makes possible transfer printing onto skins and other surfaces that did not allow conventional transfer printing due to the use of high temperature, high pressure, or glue. “The significance of the research lies in that it has confirmed for the first time that the remarkable adhesion-switching abilities of gecko setal arrays can be applied in the manufacture of various electronic devices,” said Prof. Jongho Lee. “In particular, it is expected to contribute to accelerating the commercialization of wearable electronic devices,” he added.