Media Center

A multimedia mosaic of moments at GIST

GIST Excellence

[Press release] Professor Ji Young Jo leads a research team to develop a multi-layer flexible device to convert heat into electricity

- 엘리스 리

- REG_DATE : 2016.09.20

- HIT : 892

Professor Ji Young Jo leads a research team to develop a

multi-layer flexible device to convert heat into electricity

Sponsored by the National Research Foundation of Korea, Professor Ji Young Jo of the Gwangju Institute of Science and Technology and her research team have developed a new process to increase the voltage and thermal conductivity of the flexible element, which can be used as renewable energy.*

* Renewable energy: substituting existing or fossil fuels with renewable energy, including sun, rain, water, geothermal, biological organisms

□ Flexible thermoelectric devices can replace wasted heat into electricity and has been recently identified as a renewable energy source. Flexible thermoelectric devices can be worn (wearable) in everyday life, such as in clothing, and can be utilized in greenhouses. However, a flexible thermoelectric device has problems with poor electrical conductivity, and the electricity is not transmitted well. The researchers proposed a thermoelectric device developed by introducing an organic thin-film multilayer structure* to a higher conversion rate and convert the heat into electrical energy with improved electrical conductivity.

* Organic thin-film multi-layer structure: the structure and chemical composition of different organic thin films stacked alternately

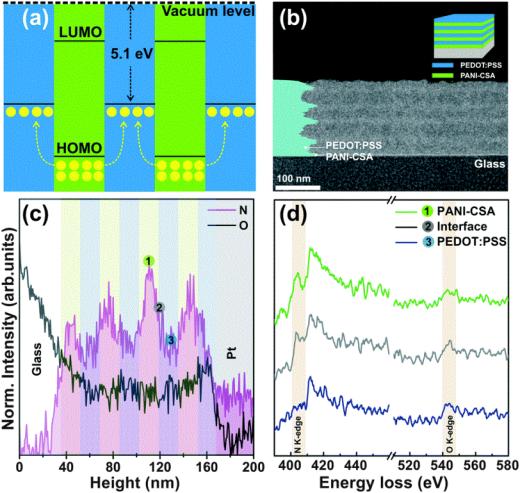

(Figure 1) polyethylene dioxy thiophene: polystyrene sulfonate / polyaniline multi-layer film structure. (A) Charge transfer that occurs between mutual films. Many of the major existing inside polyaniline (hole) are adjacent polyethylene dioxy thiophene: moves polystyrene sulfonate layer. (B) The interface of the multi-layer film. A transmission electron microscope shows that the multi-layer film with has formed a distinct boundary. (C, D) Physical and chemical reaction in the mutual interface.

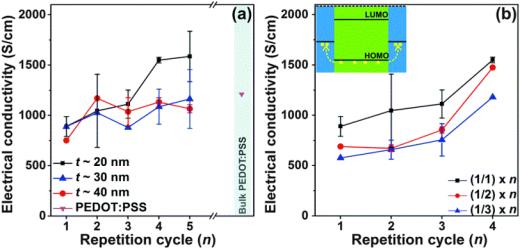

(Figure 2) Improved electrical conductivity. (A) The electrical conductivity changes according to the thickness. Polyethylene dioxy thiophene: also confirmed that the electric conductivity increases rapidly when the thickness of the polystyrene sulfonate and polyaniline is less than 20 nanometers (nm). (B) Polyethylene dioxy thiophene: a dominant role in the electrical conductivity of polystyrene sulfonic acid. Also confirmed that the electrical conductivity increase in the number of layers increases, polystyrene sulfonic acid.

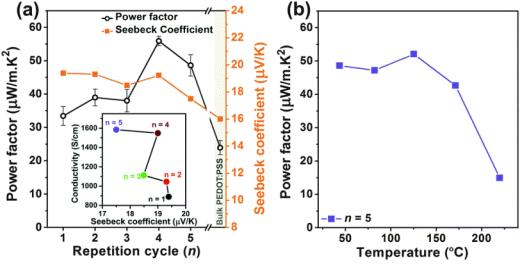

(Figure 3) Improving organic thermoelectric device performance. (A) Organic thermoelectric device performance and Seebeck coefficient. Prompt organic thermoelectric device represents a power factor performance indicator is rising rapidly in the organic thin-film multilayer structure. (B) Operable temperature environment. Even at a relatively low temperature near room temperature, it maintains a good power factor and confirms the possibility of applying the wearable device using the human body temperature.

□ Researchers introduced a flexible organic material with little or no inverse relationship between the electrical conductivity and the Seebeck coefficient *, and stacking the material in multiple layers increased the electrical conductivity. In addition, this is the world"s first organic multi-layered thin film layer to be 20 nanometers (nm) or less, and the electrical conductivity and efficiency was improved at the same time by alternately stacking different types of organic thin film.

* Seebeck coefficient of material of the material-specific factors that determine the temperature difference and hence the voltage generated in accordance with the material

□ Professor Ji Young Jo explained the significance of the research by saying: "This research is improved the efficiency of thermoelectric devices through the development of a new process to creating flexible organic thin-film multilayer structures. When used with flexible clothing or plastic housing cover, it is expected to contribute to the harvesting technology * used to charge the other element by converting the small amounts of discarded thermal energy into electricity. "

* Harvesting technology: technique for collecting energy by using a phenomenon that already exists in the system

□ The study was conducted with the support of the Korean government and GIST, and it was published on the August 31, 2016, of Energy & Environmental Science and chosen as its cover paper.