Media Center

A multimedia mosaic of moments at GIST

GIST Excellence

[Press release] Professor Dong-Yu Kim created a large-area flexible perovskite solar cell without shortcomings

- 엘리스 리

- REG_DATE : 2016.11.24

- HIT : 849

Professor Dong-Yu Kim created a large-area flexible

perovskite solar cell without shortcomings

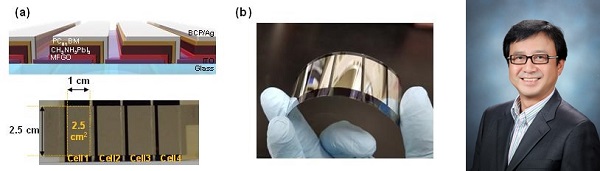

Figure 1. (a) A schematic diagram of a large-scale perovskite solar cell module and an actual photographic image are shown. (b) It can be produces on a plastic substrate, and the excellent mechanical flexibility of the solar cell module can be verified.

The organic / inorganic composite perovskite is a material that forms a compound crystal structure by combining metals, organic substances, and halogen (fluorine, chlorine, bromine, etc.). It has high photoelectric conversion efficiency * as a next-generation material that can be implemented rapidly. In addition, the material cost is much lower than that of conventional inorganic solar cells, such as silicon, and the solution process is already feasible. Thus, the perovskite solar cell is expected to be commercialized in a short period of time.

* Solution-dispersed graphene: Graphene is easy to mass-produce by solution process and easy to control and improve various performance parameters

* Photoelectric conversion efficiency: Efficiency to convert light energy into electric energy

Professor Dong-Yu Kim of the Department of Materials Science and Engineering at the Gwanghi Institute of Science and Technology (GIST) succeeded in producing a highly efficient, large-area flexible perovskite solar cell in collaboration with Dr. Han-Ik Jo of the Center for Carbon Fusion Materials at the Korea Institute of Science and Technology (KIST).

So far, perovskite solar cells have shown many possibilities. However, the high acidity and hygroscopicity of the conductive polymer (PEDOT: PSS) inserted into the interfacial layer for improving the performance shortens the lifetime of the perovskite solar cell, and high-efficiency device fabrication and basic driving principle research, and research for commercialization, such as large-area-mass production, was in the early stage.

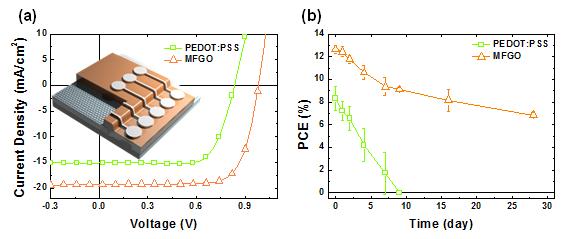

Figure 2. (a) Photo-current density-voltage curves show that the photoelectric conversion efficiency of the solution-dispersed graphene (MFGO) -based device versus the PEDOT: PSS-based device is superior. It can be seen that all the solar cell performance evaluation factors (open-circuit voltage, current density, filling rate) are uniformly increased. (b) Graphs show changes in photoelectric conversion efficiency with time (days) when a perovskite solar cell is stored in the open. In the PEDOT: PSS device, the photoelectric conversion characteristic disappears for less than 10 days, and in the case of the solution-dispersed graphene device, the photoelectric conversion efficiency is maintained at about 7% even for about 30 days.

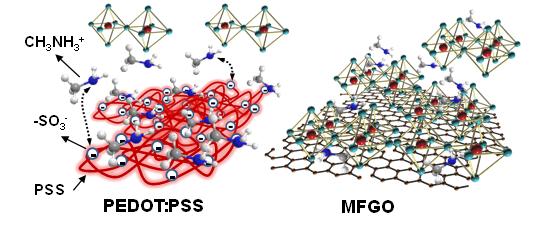

Figure 3 is a schematic diagram of the crystallization behavior of the perovskite precursor on PEDOT: PSS and solution-dispersed graphene (MFGO). Perovskite crystal films formed by ionic bonding between small ions have better crystallinity on chemically stable surfaces such as solution-dispersed graphene than surfaces with specific charge such as PEDOT: PSS.

By introducing solution-dispersed graphene, which has electrical conductivity, mechanical flexibility and chemical stability as a new interfacial layer, it achieved about 40% higher photoelectric conversion efficiency than conventional conductive polymer (PEDOT: PSS). In addition, the perovskite thin film based on the solution-dispersed graphene film compared to the conventional conductive polymer (PEDOT: PSS) remarkably improves the crystal orientation and crystallinity. In addition to the excellent properties of graphene itself, it has been found that the interaction of graphene with perovskite influences perovskite crystal properties and the overall device performance and stability.

Using a graphene solution, the team applied all the procedures necessary for the fabrication of a perovskite solar cell device to a simple solution process, and produced a large-area, 10 cm2, (flexible) perovskite solar cell module.

"This is the first successful application of large-area device applications for solution-dispersed graphene," said Dr. Han-Ik Jo of the Research Center for Carbon Fusion Materials at KIST. The low-cost/high-efficiency large-area flexible perovskite solar cell implementation is achieved through perovskite solar cells, and I think this will be an important cornerstone for commercialization. "

This research was carried out as a unique project of KIST with the support from the Ministry of Science, ICT and Future Planning (Minister Yang-hee Choi). The results of the research were published online on November 1, 2016, in Elsevier"s Nano Energy (IF: 11.553). The first author of the paper is Dr. Joon Seok Yeo, a postdoctoral researcher, and was the result of joint research with GIST Professor Professor Dong-Yu Kim.