Media Center

A multimedia mosaic of moments at GIST

GIST Excellence

[Press release] GIST 4D printing simulator wins Global SW Competition award

- 엘리스 리

- REG_DATE : 2016.11.29

- HIT : 888

GIST 4D printing simulator wins Global SW Competition award

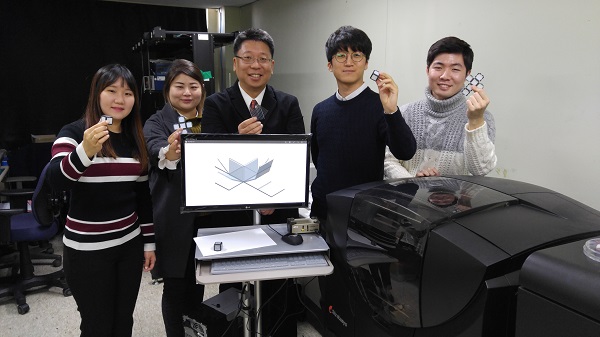

Professor Yong-Gu Lee (center) won the future scientific creation prize at the Global SW Competition

□ Gwangju Institute of Science and Technology (GIST) Professor Yong-Gu Lee won the future scientific creation prize (silver prize) at the 28th Global SW Competition.

∘ The Global SW Competition is hosted annually by the Korea Institute of Science and Technology (KISA) and the Korea Software Industry Association (KITA) to discover new ideas and software (SW) experts in the field.

□ Professor Yong-Gu Lee and master"s student Hae-won Seon, Kyoung-seok Noh, Tae-young Kim, and Hyun-ju Ko comprised the "Smart 3D Printing Research Team" that created software to simulate 4D printing objects that change according to time and proposed a shape deformation prediction simulator for the printed object.

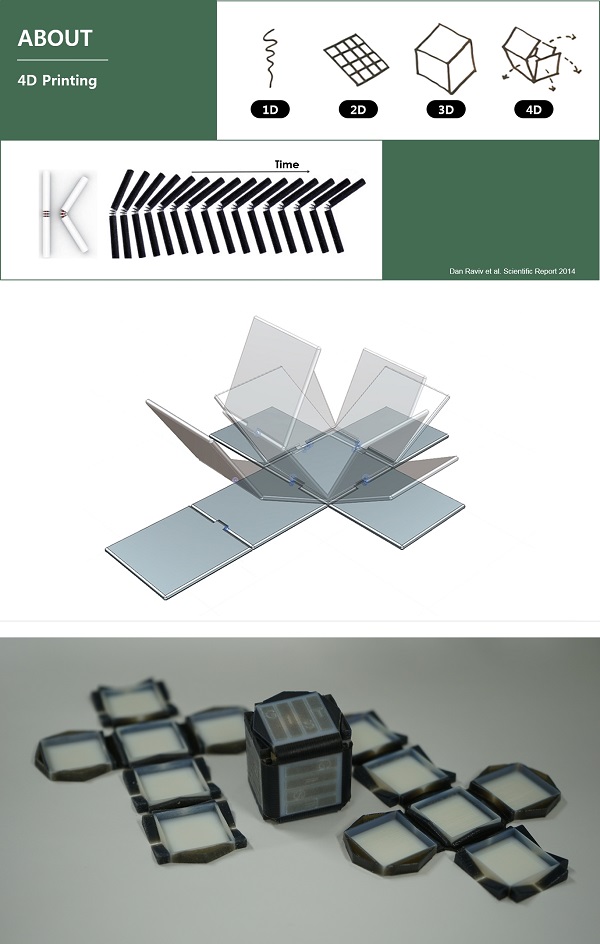

∘ (4D Printing) 4D printing, which the government is developing as a future strategic business, applies the fourth-dimensional concept of time to 3D printing.

∘ (Project Team) Professor Yong-Gu Lee has been working on 4D printing simulators, such as "4D printing simulator technology" as supporting technological development project of the IT.SW fusion industry, which is promoted by Ministry of Science, ICT and Future Planning.

* Project name: 3D graphic contents management simulator which can utilize creative materials

∘ (Award-winning works) The SW proposed by the research team simulates the motion of a shape memory alloy (SMA) applicable to 4D printing and shows the process of deforming the shape of the 4D printing object to the user, which can show whether there is an error in the changing shape of the object.

* Shape Memory Alloy (SMA): Alloy that changes shape temporarily when a certain temperature or stimulus is given and then can return to its initial state.

(Top) A schematic diagram illustrating the concept of 4D printing. (Middle) The image when viewing the cube transformation process with the 4D printing simulator developed by Professor Yong-Gu Lee. (Bottom) Photograph of actual cube made by the research team.

□ (Core Technology) The core technology of 4D printing is based on how the final object will result from the initial form when using a 3d printer. Based on the normalized data input to the simulator, "4D Printing Simulator", developed by Professor Yong-Gu Lee and his team, can predict changes in output over time considering the shape, physical properties, and external environmental factors of the output to 3D printer.

∘ Inversely, it is possible to predict the initial state of an object to be printed with a 3D printer in order to obtain the final changed shape.

(Future Plans) The team plans to expand the software"s capabilities to simulate not only shape-based alloy (SMA) but also other smart materials, such as hydrogels * and shape memory polymers * that can be applied to 4D printing.

* Hydrogel: It has a property of expanding than the initial state due to water, temperature, pH, etc.

* Shape memory polymer (SMP): A polymer that returns to the initial state from a temporary strain applied when a certain temperature or stimulus is given.

□ Professor Lee said, "Using the proposed software can effectively reduce the time and cost of producing 4D printed objects. We will standardize the predicted values based on the external environmental factors, such as temperature, humidity, pH concentration, and 3D printing materials, and we plan to open the server on the Internet so that other researchers can share it."

□ (Awards Ceremony) The 28th Global SW Competition will be held at the "17th SW Industrial Company Day Ceremony" held at COEX in Seoul at 5:30 pm on Monday, November 28, 2016.